How to Make Data Actionable for Facility Management

For the sake of reliability, facility owners and operators spend time and resources repeating processes like verifying as-built conditions, formatting data for entry into their maintenance management systems, and indexing the right information to the right asset. This creates waste in terms of rework and creates a large gap between the time a facility is certified for occupancy and when accurate and reliable information is available to maintain it. It's time to change that.

Arundhati Ghosh, PhD. specializing in BIM, Facilities Management and Owner Operations for VueOps™ discussed how the industry can close the gap between the time a facility is certified for occupancy and when accurate information is available to maintain it.

Simply stated, the information lifecycle of a construction project begins with the architect/engineer creating drawings and specifications, the contractor procuring, fabricating, and installing material at completion, and the project team handing over the ‘as-built’ documentation to the facility owner and operator. This linear process is punctuated by several rounds of information exchanged between stakeholders looking at it with varying perspectives. At the end of a multi-year construction project, it is likely that information that has passed through multiple people and formats includes errors and omissions.

For the sake of reliability, facility owners and operators spend time and resources repeating processes like verifying as-built conditions, formatting data for entry into their maintenance management systems, and indexing the right information to the right asset. This creates waste in terms of rework and creates a large gap between the time a facility is certified for occupancy and when accurate and reliable information is available to maintain it. The facility owner can also lose significant revenue in this transition. Often facility operators make-do with what is available and suffer the consequences at a later time. We can trace the root cause for data issues to two reasons; incomplete understanding of operational needs by the project teams, and insufficient owner specified definitions for data handover.

To create a database that facility operators can rely on, we need to identify the scope for information requirements, and the process for authoring, verifying, and transferring the information to the owner’s systems, while considering the workflows of design and construction stakeholders. At VueOps, we developed the Facility Data Specification (FDS)© as a response to this need. The FDS is a specification and a process tool that tells designers and contractors what information facility operators need, and how the project team can deliver the information.

[FDS] Specification

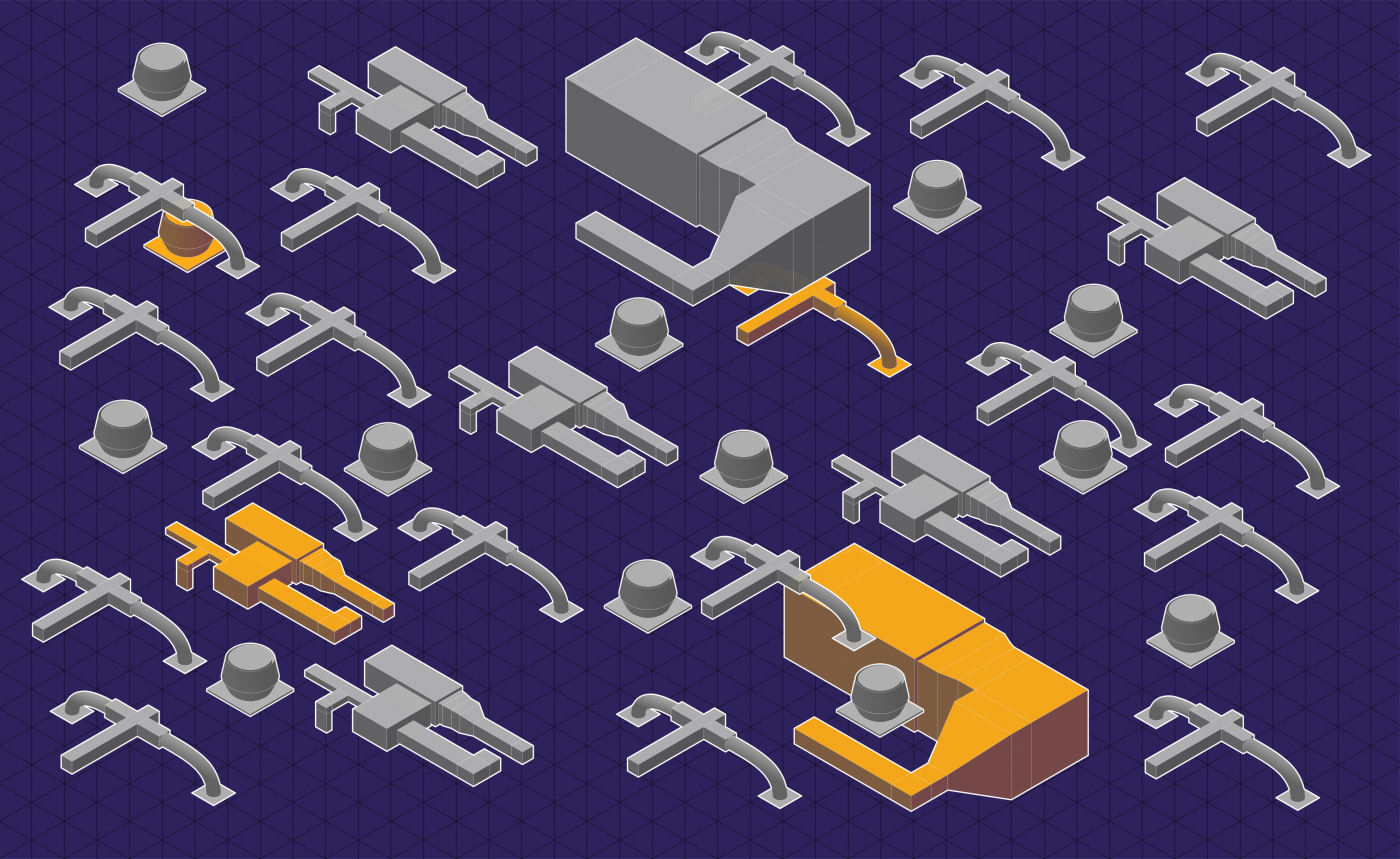

The FDS establishes standard naming criteria to identify an asset across multiple systems, and the corresponding data schema that serves the operator’s use-cases. For example, designers represent the domestic water system in construction drawings by a single line diagram with valves and plumbing fixtures represented as symbols, and notes and specifications providing further information about the equipment. The designer or the trade partner who builds a 3D model for this system, will typically model to the level of development defined by the BIM-use, such as geometrical coordination and/or fabrication.

Now imagine there is a water leak and the facility operator has to trace the source and the shut-off a valve to prevent further damage. For an operator, the information that was turned over in the project documentation is useful only when they can diagnose a faulty valve by viewing the domestic water system in its entirety with the exact valve, access zone, and plumbing fixture locations; along with key information for the valve type.

Where do they find this information and how do they know that it is reliable? Is the valve naming consistent across the construction documents, models, and maintenance management systems so that they can quickly isolate it and derive reports about the faulty valve? Did they owner specify what they need in the first place?

[FDS] Process

Going back to the water leak scenario, the FDS specifies the assets that the facility operator would like to visualize as part of the domestic cold-water system. It also defines the data the operator would like to track for the assets. Example, the operator may want to track the type, size, and material of the pipes or they may want to know the manufacturer, model, serial number, and designed head pressure for the pump.

Multiple authors create data during different times or phases in the project. The FDS provides a decision matrix for project participants to decide who is responsible for each asset and associated data, whether they need to model it, and when they are responsible to deliver the data. If desired, this allows the incremental build-up of data in smaller chunks, preventing a mountain of information at the time of handover. Further the FDS establishes a scalable and repeatable process for checking data quality at specified milestones. Data quality is an essential component of making facility databases flow from design and construction into the owner’s facility management systems.

VueOps helps owners make better decisions with their data. VueOps’ Facility Data Specification provides a framework for owners to specify what they need based on how they would like to visualize information to serve their use-cases. VueOps consultants work with designers and contractors to collect, validate, and transfer data to the owner’s systems, ensuring reliability and efficiency.